How do I adjust the scoring blade?

Operation

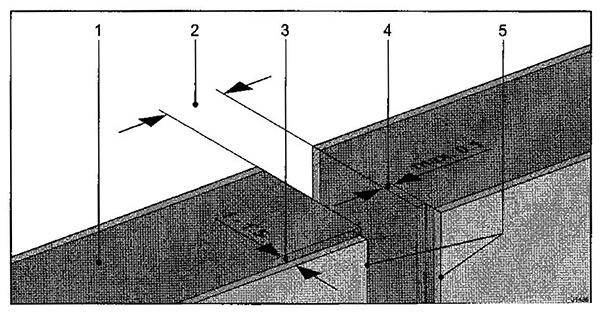

Geometry of a scoring cut

The scoring and separating cut made on a plastic laminated panel is as follows if a two-part scoring saw is used for the purpose of scoring.

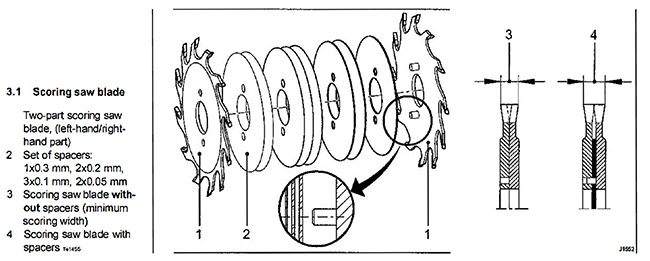

Scoring saw blade

A variety of scoring saw blades are available from the trade. The choice of the right scoring saw blade is not only dependent on cutting tool mounting but also on the material to be cut and its application. STRIEBIG recommends two-part tungsten carbide scoring saw blades with which all the adjustment options of the entire scoring saw set can be fully exploited.

The scoring saw must have the following dimensions:

Nominal diameter – 80mm

Hole diameter – 20mm

Max. width – 3.6mm

Stated speed max. – 15,000 min or higher

In order to set the scoring saw blade, it is necessary to know the width of the scoring saw blade without any spacers (measure it with a vernier caliper). In addition, the tooth width of the main saw blade must be known as well as the amount by which the scoring saw edge must stand back from the panel edge.

This information is dependent on the cutting tool or the material although the scoring width is generally approx. 0.2 mm wider than the separation cut of the main saw. The width of the scoring saw blade is set by using the appropriate spacers in accordance with this information.

For example:

Main saw blade width: 3.2mm

Desired scoring width: 3.4mm

Scoring saw blade width excl. spacer: 2.8mm

Thickness of the spacers: 0.6mm

1 x0.3 mm, 1×0.2 mm and 1×0.1 mm spacers must be used from the existing set of spacers.

True running can only be achieved when the saw blade shaft, the clamping flange and the saw blade centre are perfectly clean.

The selection of spacers provided contains more spacers than are required to set the maximum permissible scoring width. The additional spacers are spare spacers in the event of one or more being damaged as a result of creasing, etc.

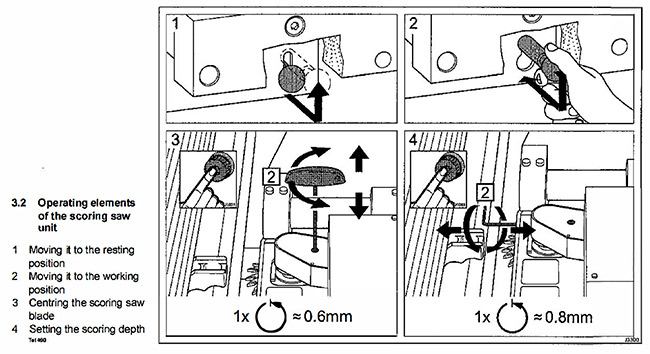

Operating elements

The scoring saw unit has the following operating elements:

1. Operating rod. This is used to move the scoring saw unit into its working position or its resting position. The scoring saw unit is moved from its working position to the resting position by pulling and slightly raising the ball grip on the operating rod. When moving from the resting position to the working position, guide the operating rod by holding the ball grip. Do not allow the scoring saw unit to be forced back into its working position by the pressure of the spring!

2. Centrlng the scoring saw blade. The screw used to set the scoring saw blade centring is located in the cover of the scoring saw unit and allows the blade to be aligned with the main saw blade. To do this, the saw unit must be swung into the horizontal position and the scoring saw unit must be in its working position. Dependent on the direction of rotation, the scoring saw blade shaft is displaced axially by approx. 0.6 mm per turn. The direction of rotation and the adjustment travel per turn of the key are given on stickers on the extraction hood.

3. Setting the scoring depth. This adjuster is fitted in the extraction hood. The adjustment screw can be accessed through a hole in the extraction hood baseplate. It can be operated independently of the cutting position of the saw unit. Dependent on the direction of rotation, the scoring depth is changed by approx. 0.8 mm per turn.

The direction of rotation and the adjustment travel per turn of the key are given on stickers on the extraction hood.

Find More Troubleshooting Suggestions

Striebigs are extremely reliable when maintained properly. If you experience an issue and would like to troubleshoot independently, below are a few procedures to address them.

Please note: Some procedures refer to parts that may differ slightly from your Striebig model. If you have questions, please contact Colonial Saw.

Filter by Topic

Why am I cutting into my grid laths?

Replacing Grid Deflecting Device Assembly (C) Models – Econom, Standard, Optisaw 1, Optisaw I Plus, Optisaw II & Standard TRK machines With saw head horizontal: 1. Unhook thinner spring #56 from carriage safety brake bolt #21. 2. Back off Allen head set screw just below bolt #20 holding top of hollow rod with 3mm Allen…

See Full AnswerHow do I adjust the scoring blade?

OperationGeometry of a scoring cut The scoring and separating cut made on a plastic laminated panel is as follows if a two-part scoring saw is used for the purpose of scoring. Scoring saw blade A variety of scoring saw blades are available from the trade. The choice of the right scoring saw blade is not…

See Full AnswerWhere does the rod with 2 brass ends go on my saw?

Replacing Grid Deflecting Device Assembly (C) Econom, Standard, Optisaw 1, Optisaw I Plus, Optisaw II & Standard TRK machines With saw head horizontal: 1. Unhook thinner spring #56 from carriage safety brake bolt #21. 2. Back off Allen head set screw just below bolt #20 holding top of hollow rod with 3mm Allen wrench. With…

See Full AnswerHow do I replace the deflector mechanism?

Replacing Grid Deflecting Device Assembly (C) Econom, Standard, Optisaw 1, Optisaw I Plus, Optisaw II & Standard TRK machines With saw head horizontal: 1. Unhook thinner spring #56 from carriage safety brake bolt #21. 2. Back off Allen head set screw just below bolt #20 holding top of hollow rod with 3mm Allen wrench. With…

See Full AnswerWhy do my measured dimensions move when I plunge the head in to cut?

Adjusting the carriage locking (brake) mechanism 1. Remove the deflecting device as above 2. Loosen the setscrew for the backing screw (also on the left side of the carriage-shown just below the “Striebig” nameplate in the drawing) 3. Make adjustment to the backing screw #32 from behind with 6mm Allen wrench so that the screw…

See Full AnswerWhy are my cuts burning and chipping?

Parallel Guide (Healing/Tracking) Adjustment for Striebigs Models – Econom, Standard, Automat, Optisaw I, Optisaw I Plus, Optisaw II & Standard TRK 1. Test for healing by making a climb-scoring (or main-blade scoring) pass and returning back through with a finish cut. Retract the riving knife (splitting wedge) before cutting. The test is the same, but…

See Full AnswerHow do I square my saw cuts?

Test cutting and squaring an Econom, Standard, Automat, Optisaw I, Optisaw I Plus, Optisaw II, Optisaw II, Optisaw Automatic & Standard TRK The intent of these instructions is to accomplish this efficiently and accurately, with minimal amount of material usage. It is important the frame is level and is not sagging or raised in the…

See Full AnswerHow do I adjust the step out of my cut that occurs while backscoring?

Parallel Guide (Healing/Tracking) Adjustment for Striebigs Models – Econom, Standard, Automat, Optisaw I, Optisaw I Plus, Optisaw II & Standard TRK 1. Test for healing by making a climb-scoring (or main-blade scoring) pass and returning back through with a finish cut. Retract the riving knife (splitting wedge) before cutting. The test is the same, but…

See Full AnswerHow do I change a motor belt?

Procedure for Removal and Installation of Motor Drive Belt for Striebigs Models – Econom, Standard, Automat, Optisaw I, Optisaw I Plus, Optisaw II & Standard TRK 1. Disconnect power to saw. 2. Rotate head to the horizontal cutting position. 3. Position and lock carriage to a comfortable working height. 4. Open belt cover (item #8).…

See Full Answer