Photo Credit - Sunrise Erectors Inc.

Aluminum sheet and ACMpanels, as well as other non-ferrous panels can be easily handled, cut and/or grooved on any STRIEBIG model.

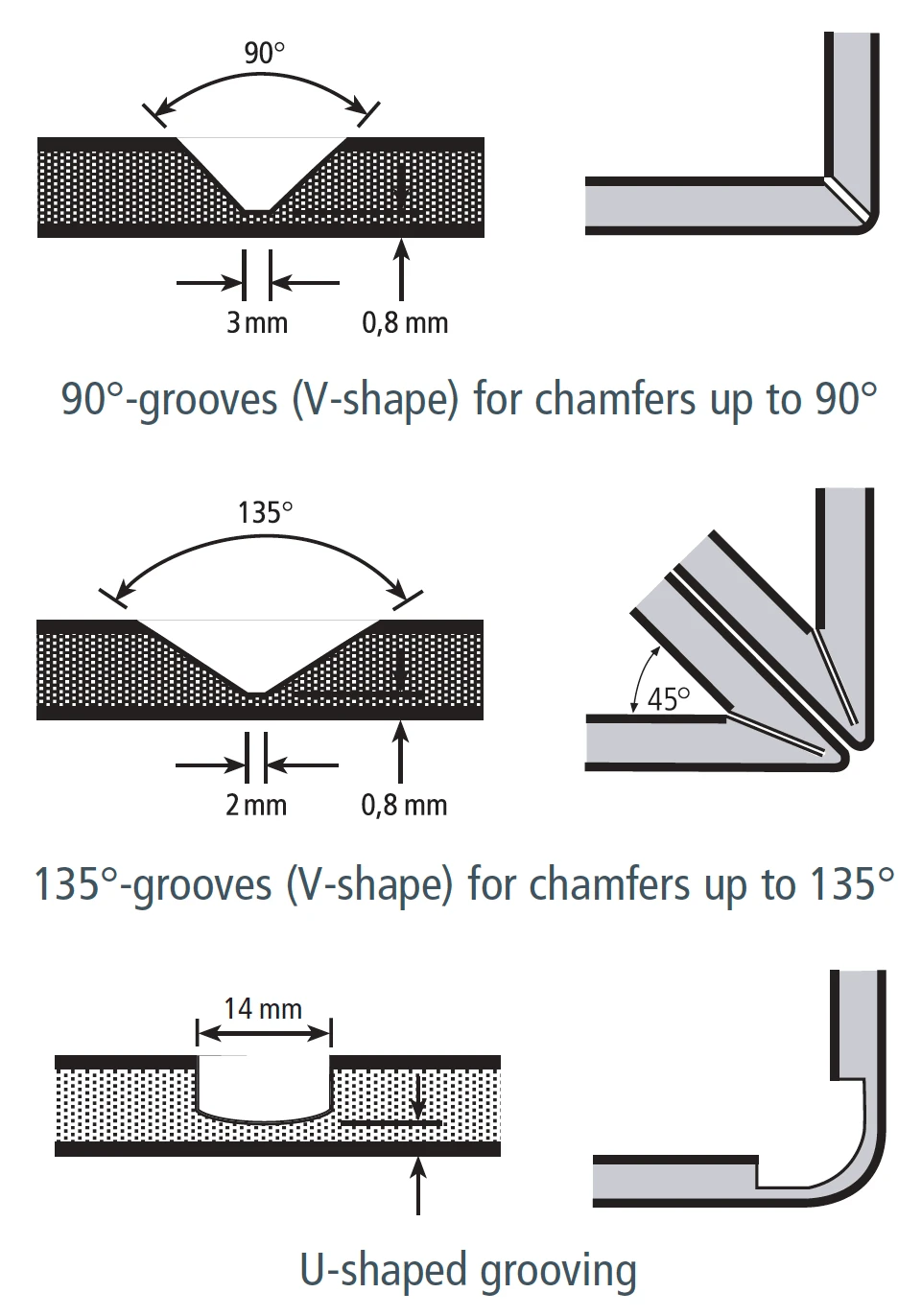

STRIEBIG worked with AluSuisse, the inventor of ACM, to develop the grooving accessory and various grooving cutters for ACM panels, so that fabricators could more easily rout accurate and consistent grooves for bending the panels.

The Saw Composite Panel Manufacturers Recommend!

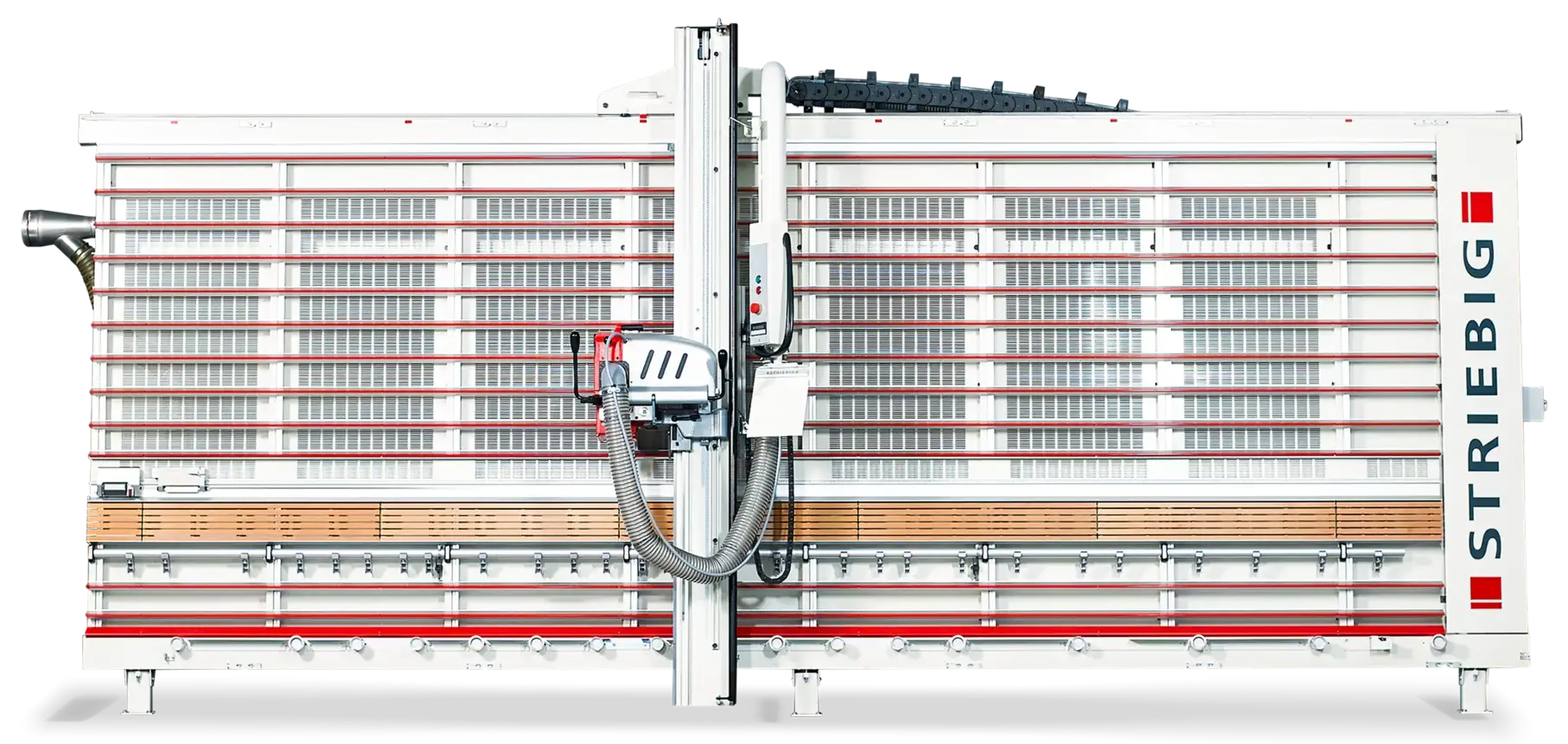

Shown Above, Striebig's Compact model is available in both manual and automatic traveling versions and can be enhanced by adding a wide range of accessories, including digital measuring, grooving, and even angle cutting. Its flexibility and attractive price make it the most popular choice among ACM fabricators, and it is usually ordered in the larger frame size to accommodate the common 196” x 62” sheets.

Striebig also offers the Standard, Evolution, and Control models to ACM fabricators.

Recognizing the importance of the construction panel industry, Striebig offers ACM Fabricators an ACM grooving attachment to fit all their saws. This grooving attachment, developed by Striebig, allows fast, accurate, and reliable 2-axis sawing and grooving in all panel thicknesses.

Striebig Advantages

Simple, safe operation - Short learning curve for employees, and the saw blade is always covered

Space saving - Striebigs take up much less floorspace than other types of saws

Accurate - Cuts perfectly square to within .004”!

Versatile - Smooth, high-quality cuts in a wide range of building materials, including OSB, CDS, melamine, composite trim, insulated foam board, etc.

Ease of use - Easy to handle large sheets safely and fatigue-free

For the optimal machining of composite panels, every Striebig panel saw can be equipped with a special "ALU" package. Standard equipment is the grooving device, and optional equipment is the profile cutter with rever- sible carbide tips for composite panels.

Vertical Panel Saw Streamlines Fabrication of Aluminum Composite Material

Learn how Karas & Karas Glass Co. Inc. uses a STRIEBIG to fabricate ACM.