Hybrid Zeta P2 + CNC Positioning Pin Method

Possible Combination of CNC Machines with Zeta P2

Precise drilling on a CNC machine, use these drill holes to position the Zeta P2 to cut the

P-System grooves. This application is especially ideal if the CNC machine is a nesting machine

and or no aggregate is available. This method combines the precision and efficiency of a

CNC machine and uses the simple and fast machining of a P-System groove with a Zeta P2.

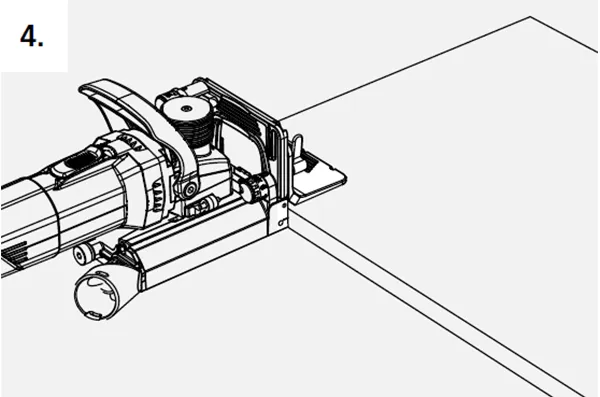

How it works: P-System groove in the surface

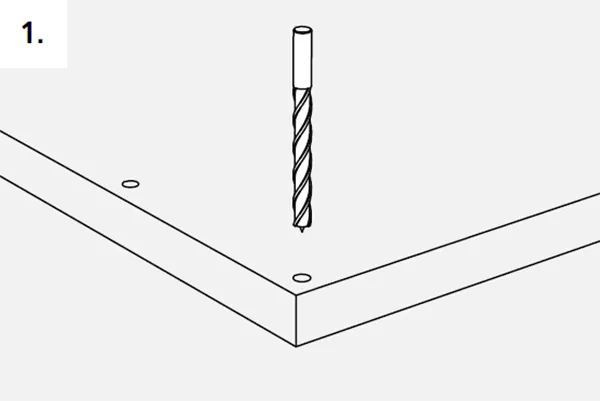

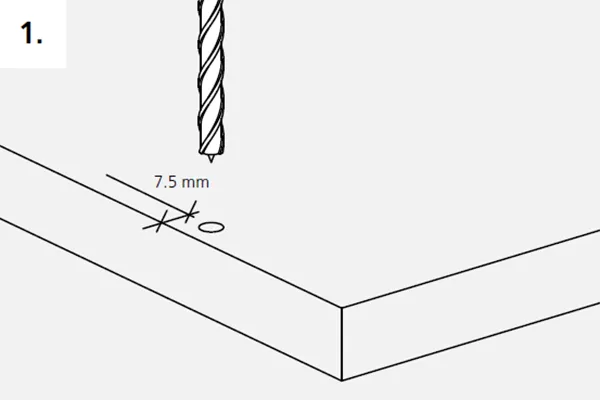

Steps 1 &2- positioning drill holes for the Zeta P2

Drill the positioning holes with the CNC, Ø 5 mm/Ø 8 mm

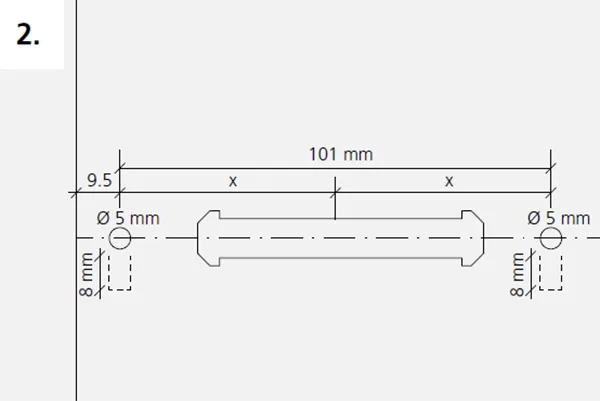

Hole pattern of the positioning drill holes axis spacing 101 mm

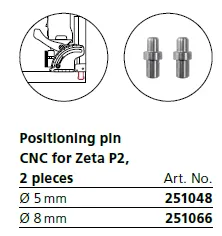

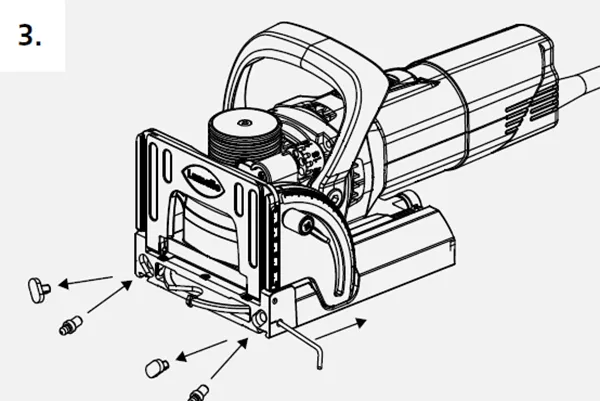

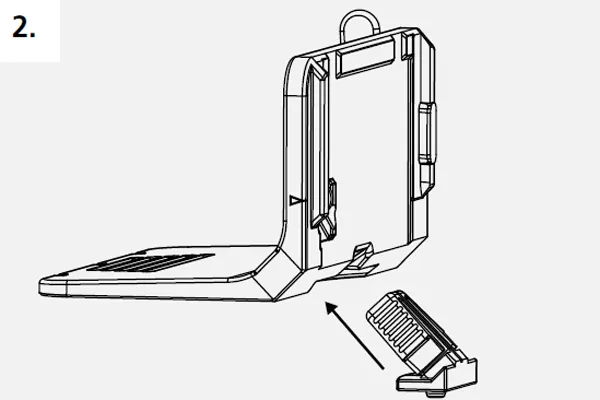

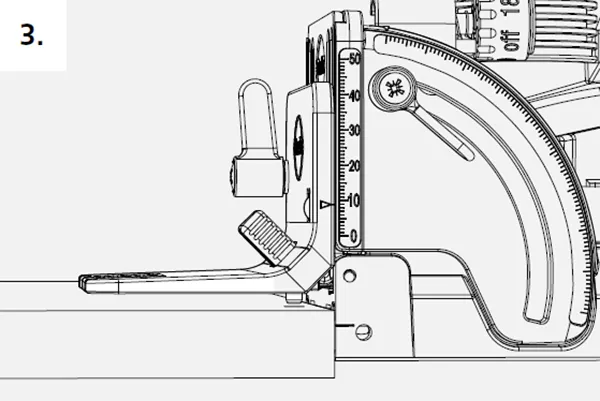

Steps 3 & 4 – positioning pin CNC for Zeta P2

Insert the positioning pins in the Zeta P2

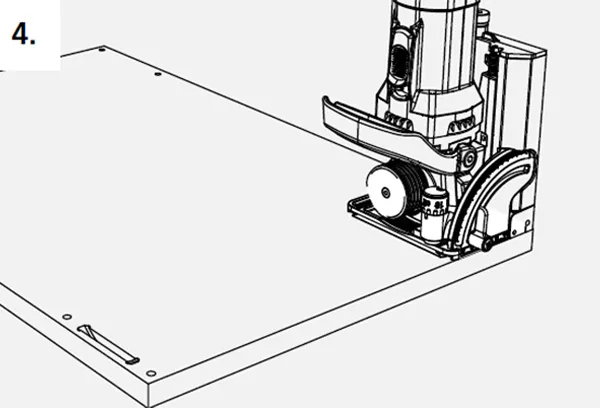

Position the machine in the drill holes

P-System groove in the edge

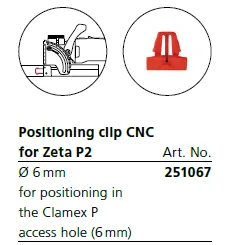

Steps 1-4 Positioning clip CNC for Zeta P2

Drill the positioning hole with the CNC, Ø 6 mm

Insert the positioning clip

Insert the positioning clip in the drill hole Ø 6 mm

Cut the groove with the positioned machine

Related Products

Sorry, we couldn't find any posts. Please try a different search.