Cutter Differences – Carbide vs. Diamond

Curious about the differences between carbide and diamond cutters? Our video explains their uses and advantages.

Video Transcript: Hey everyone, this is Chris, the U.S. Product Manager for Lamello. I want to give you a brief explanation of the differences between the carbide cutters and diamond cutters, the P-System cutter used with the Zeta P2, and why you might choose one over the other.

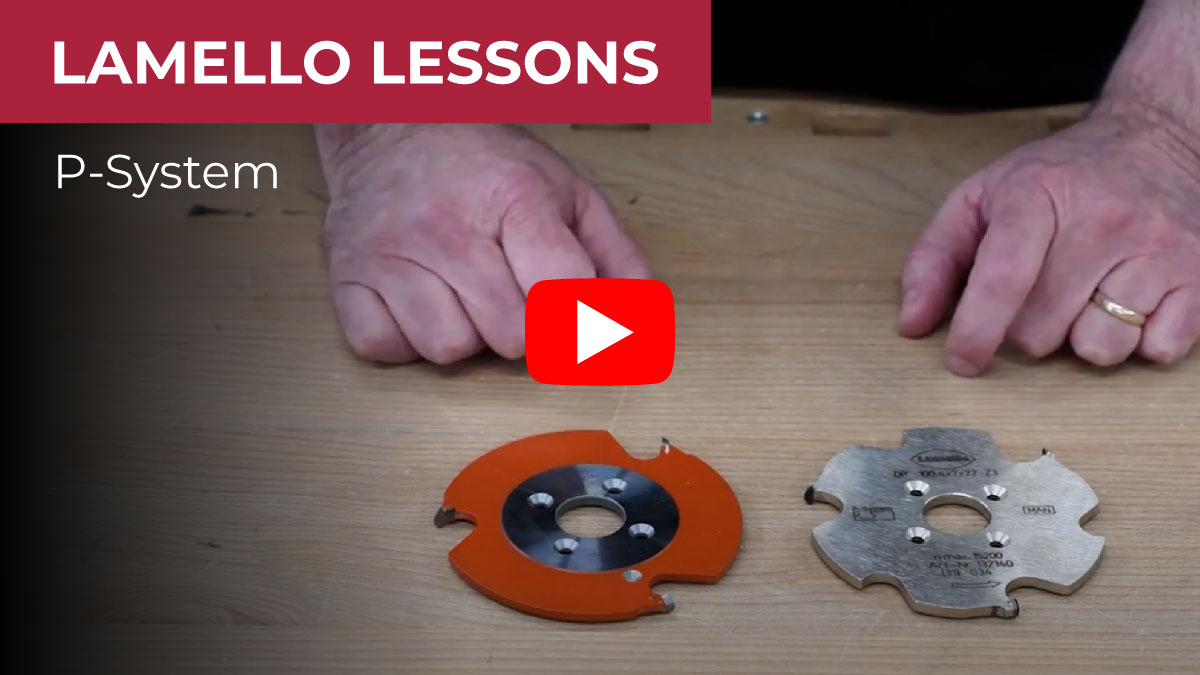

It’s easy to tell them apart at a glance. The carbide cutter has an orange body, while the diamond cutter has a silver-plated body. The carbide cutter can be sharpened, and I recommend checking out our other YouTube video, “How to Change the Cutter on Your Lamello Zeta P2,” which explains how to change the cutter and make depth adjustments.

The carbide cutter is ideal for natural wood, especially dense hardwoods like ipe, rock maple, or quarter-sawn white oak. While it doesn’t last as long as the diamond cutter, it has a technically sharper edge, making it a good choice for those tough materials. Both cutters have three cutting teeth and a 22 mm bore to fit exclusively in the Zeta machine. The carbide cutter can also be used for materials like MDF, particle board, and plywood. However, adhesives in plywood and similar materials will dull the carbide cutter faster than solid wood. Under normal usage, carbide cutters typically last for about 1,000 to 1,500 slots before needing to be sharpened.

In contrast, the diamond cutter has a PCD coating on its carbide teeth. As long as you don’t damage the teeth—this applies to both carbide and diamond cutters—the diamond cutter can last for up to 10,000 slots. This makes it highly recommended for abrasive materials like MDF, particle board, and plywood. Even in less abrasive materials, you can expect a lifespan of roughly 10,000 slots.